MicroSquirt VR2 issues

Sat 14 Nov 2009 Filed in: MicroSquirt

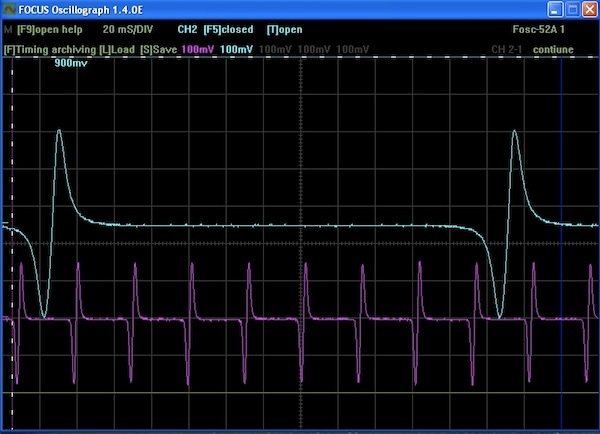

I did manage it, by using 1K across both VR outputs, but also put a single 1N007 diode between VR2- and pin 33. The trace above looks cleaner, but I have yet to test it with the cased MicroSquirt connected.

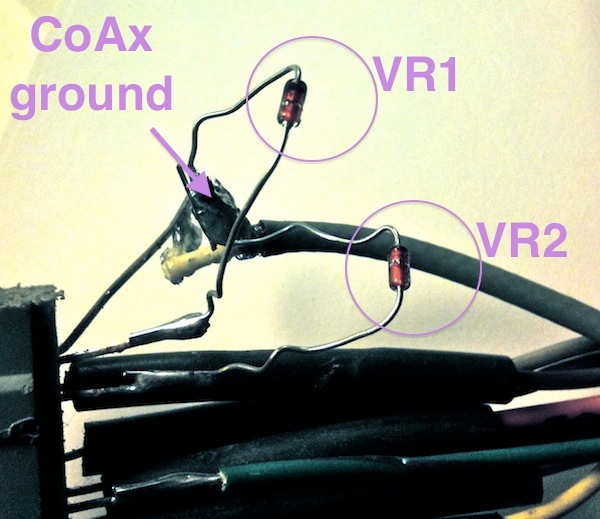

So I put two diodes polarity as shown to the common ground on the coax from the AmpSeal loom. The other ends attached to the respective VR2- of the crank and cam sensors.

Anyway this cured my issues using B&G 2.890, but shortly after I was switching to MSExtra, as the other engine wasn’t supported by this code, and I thought it made more sense from a development point of view.

In the end I discovered VR2 was less sensitive than VR1, and my fix was to reduce the cam lobe to sensor clearance, because as I did so, the cranking and sensing RPM were within the same zone.

blog comments powered by Disqus