Waiting for Panhard pistons

12/05/12 18:11 Filed in: Panhard Engine

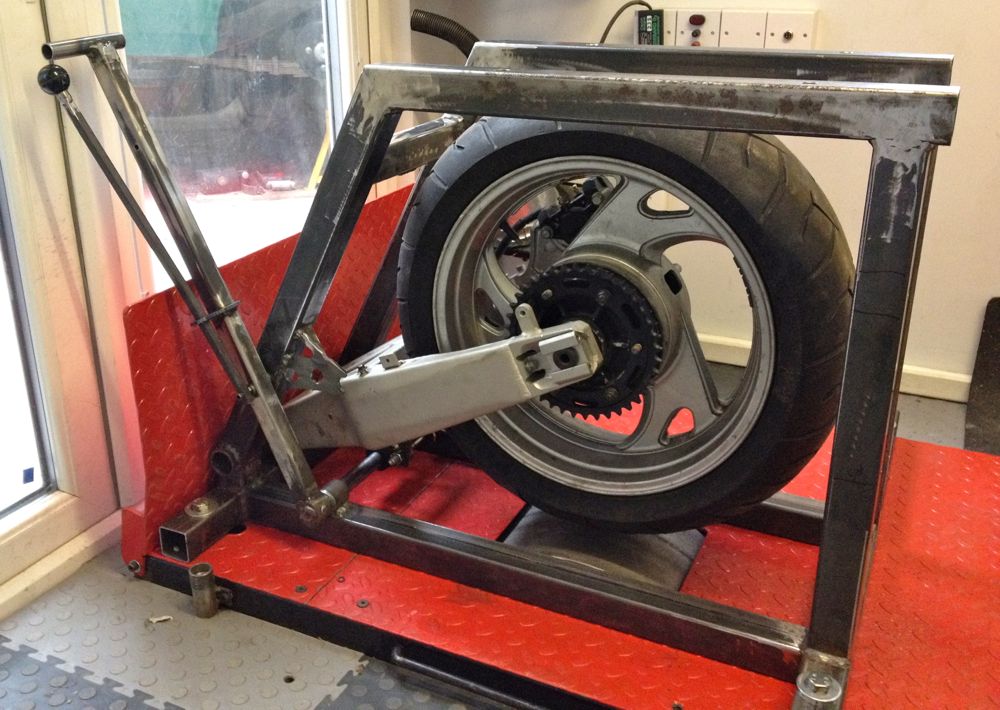

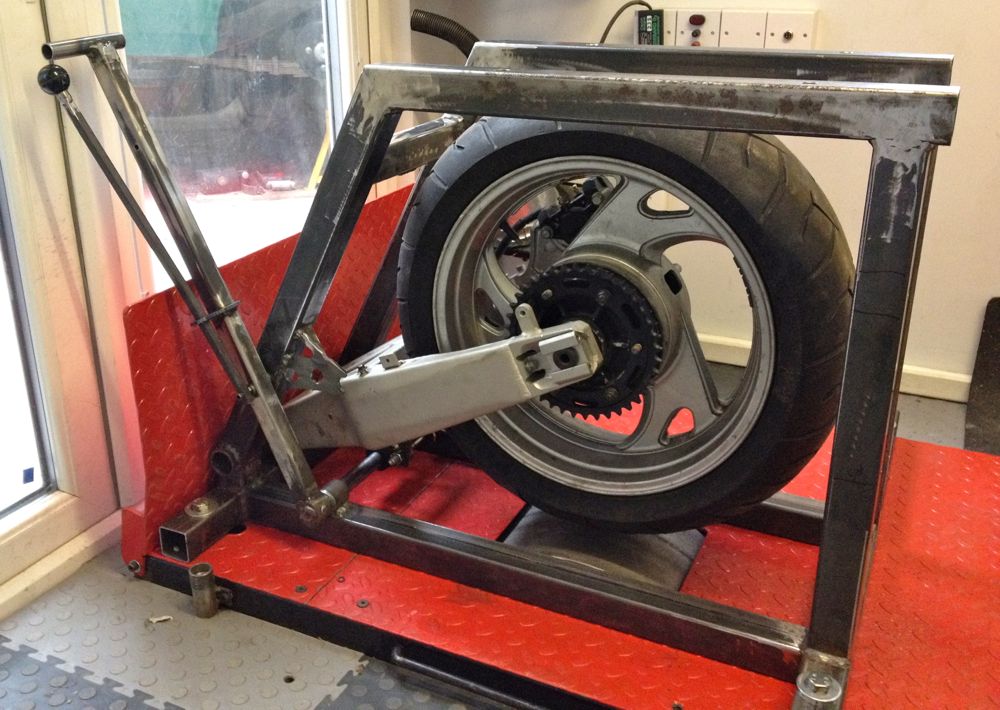

Another couple of busy weeks at work, and a bit of metal from the laser cutters has arrived. The first batch of parts were for modding the engine dyno rig, which will be need to test the Panhard engines, and the second batch are for the Whatton boring bar adaptor plates to the Elliot mill bed.

Earlier I was going to make a bespoke centrifugal clutch to isolate the inertia roller from the crankshaft sprocket, but in the interests of simplicity, I decided to remove the turnbuckle that loaded the motorcycle wheel onto the inertia roller, and replace this with a quick release tensioning mechanism. This would allow me to manually unload the engine from the dyno roller for starting and also at the end of the dyno run, just like the centrifugal clutch would do, but without all the teething problems from a bespoke design.

I still have to make a chain tensioner, but the pictures below show the unloaded and loaded positions. The wheel is loaded by pulling the T handle to the right, and simultaneously pushing the ball ended lever inwards, which disengages a sprung loaded pin from a series of circular holes, and allows the tensioning lever to move to a new position. I created an even further stop to jack the wheel clear of the frame base, so that I can manoeuvre the rig around the workshop floor.

Hopefully tomorrow, I can bolt the Panhard engine up to it, explore the tensioning options, and try and draw something up for the laser cutter.

Earlier I was going to make a bespoke centrifugal clutch to isolate the inertia roller from the crankshaft sprocket, but in the interests of simplicity, I decided to remove the turnbuckle that loaded the motorcycle wheel onto the inertia roller, and replace this with a quick release tensioning mechanism. This would allow me to manually unload the engine from the dyno roller for starting and also at the end of the dyno run, just like the centrifugal clutch would do, but without all the teething problems from a bespoke design.

I still have to make a chain tensioner, but the pictures below show the unloaded and loaded positions. The wheel is loaded by pulling the T handle to the right, and simultaneously pushing the ball ended lever inwards, which disengages a sprung loaded pin from a series of circular holes, and allows the tensioning lever to move to a new position. I created an even further stop to jack the wheel clear of the frame base, so that I can manoeuvre the rig around the workshop floor.

Hopefully tomorrow, I can bolt the Panhard engine up to it, explore the tensioning options, and try and draw something up for the laser cutter.

blog comments powered by Disqus