May 2013

Panhard 2012 Engine Installed Part 1

14/05/13 20:18

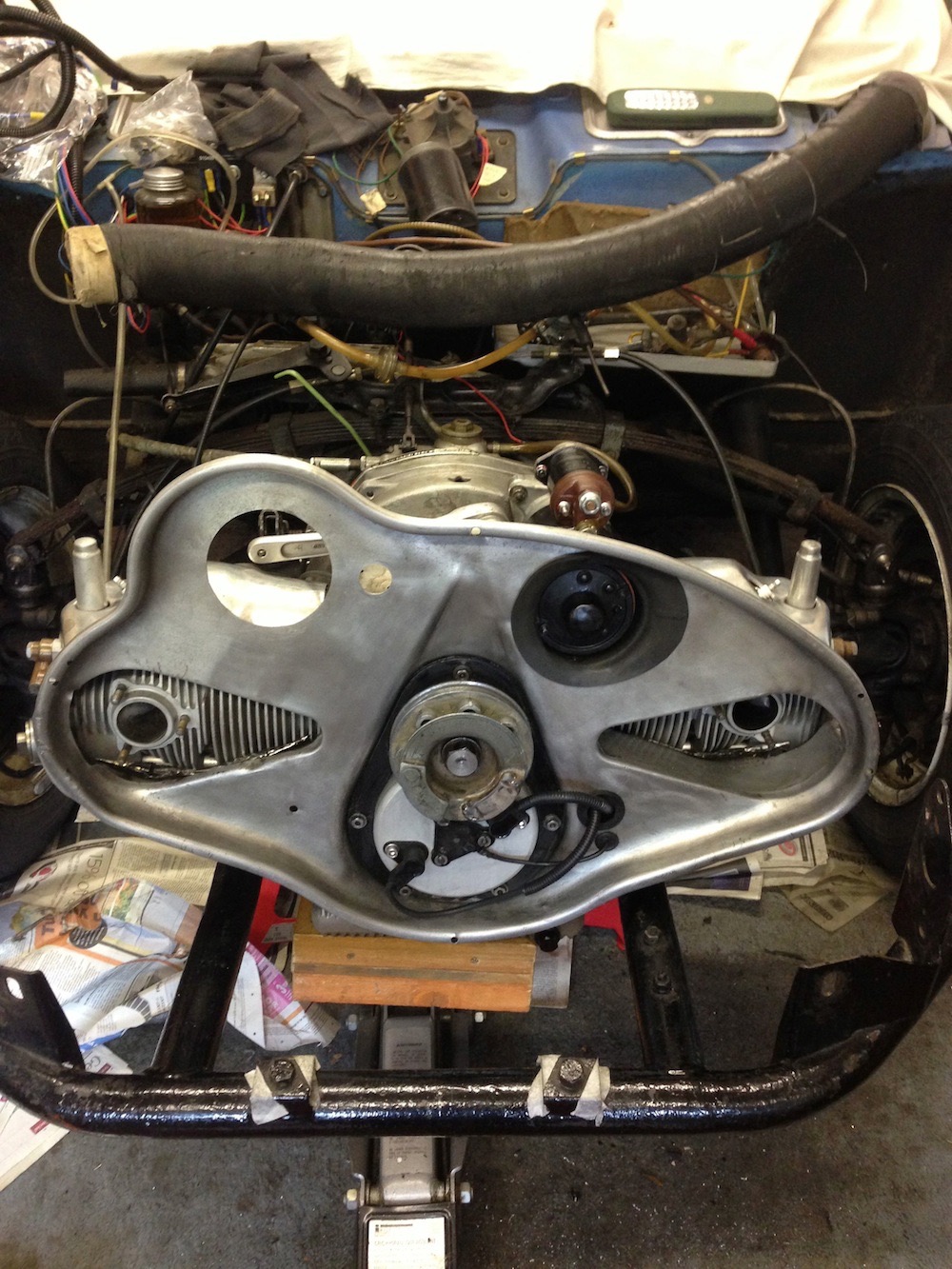

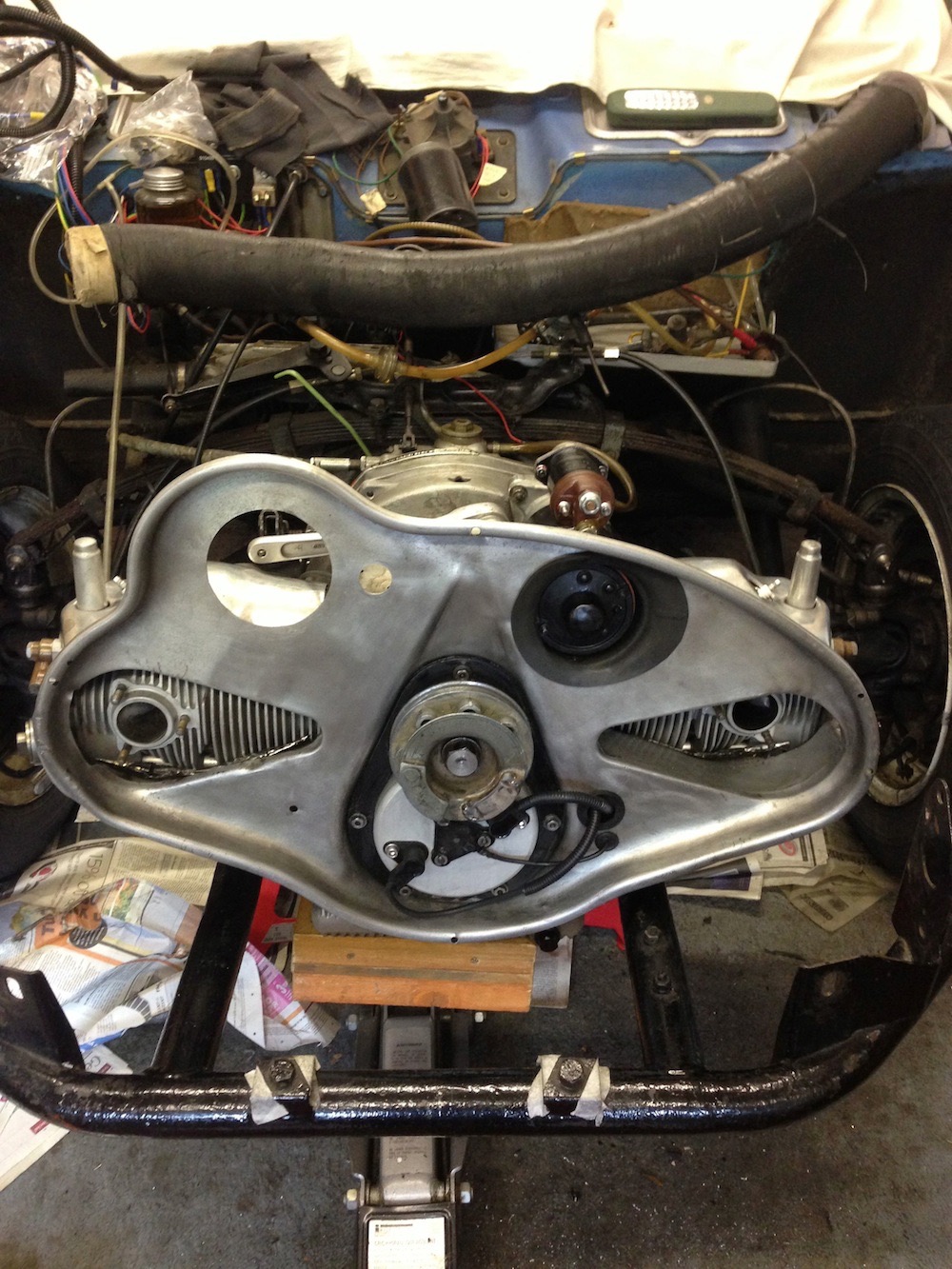

Over the course of the day, the 2012 engine is getting installed in Brian’s car

Exhausts not fastened up yet, and no wiring. MOT booked for 14:00, which might be a tad optimistic!

Exhausts not fastened up yet, and no wiring. MOT booked for 14:00, which might be a tad optimistic!

Comments

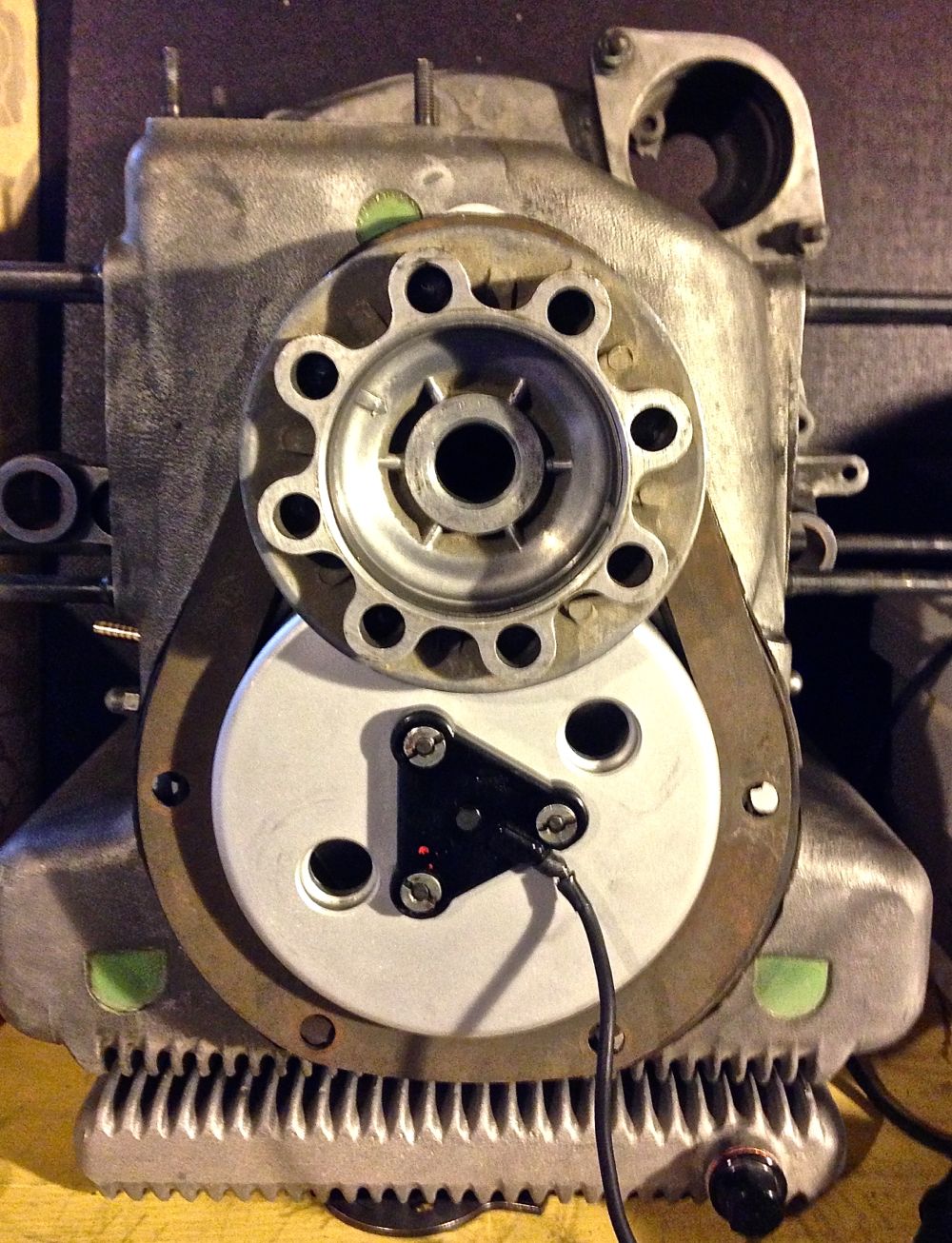

Panhard 2012 Engine Assembled

13/05/13 16:45 Filed in: Panhard Engine

I have just finished the assembly of Brian’s engine, aka the 2012 engine. As the deadline approached and some pieces became unavailable (crankshaft issues forced the changes), the planned developments changed and Brian’s engine now includes

JE higher compression pistons,

New redesigned cylinder liners with revised tolerances.

Modified porting to inlet & exhaust

Recut & re-profiled valve seats

Peter Breed Rallye Crankshaft

Peter Breed lightened flywheel and clutch assembly

Revised oil circuits

Greater oil capacity by fitting M. Joel Brunel’s double sump (modified to take O ring seals & filter plate)

New & bespoke second generation Internal oil filter (Yamaha motorcycle)

Viton oil seal to rear crankshaft bearing

Viton oil seal to front bearing

CNC alloy front timing cover incorporating ignition sensors.

Imfsoft IgnitionTCI 6.1 Programmable Ignition

Twin plugged cylinders with Bosch Twin Single Fire Coils

MAP sensor

So hopefully in a few days, it’ll be Almen here we come.

JE higher compression pistons,

New redesigned cylinder liners with revised tolerances.

Modified porting to inlet & exhaust

Recut & re-profiled valve seats

Peter Breed Rallye Crankshaft

Peter Breed lightened flywheel and clutch assembly

Revised oil circuits

Greater oil capacity by fitting M. Joel Brunel’s double sump (modified to take O ring seals & filter plate)

New & bespoke second generation Internal oil filter (Yamaha motorcycle)

Viton oil seal to rear crankshaft bearing

Viton oil seal to front bearing

CNC alloy front timing cover incorporating ignition sensors.

Imfsoft IgnitionTCI 6.1 Programmable Ignition

Twin plugged cylinders with Bosch Twin Single Fire Coils

MAP sensor

So hopefully in a few days, it’ll be Almen here we come.

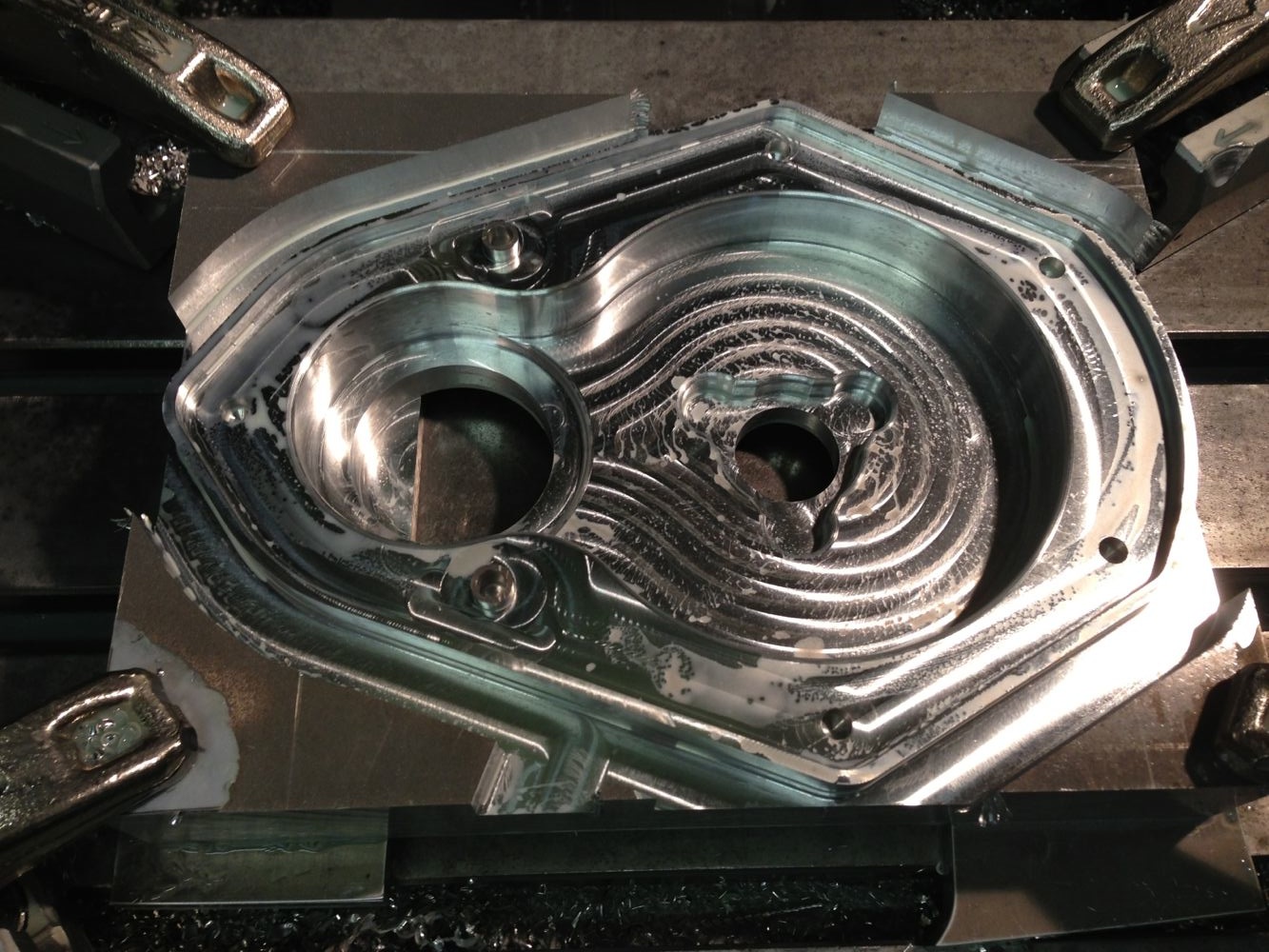

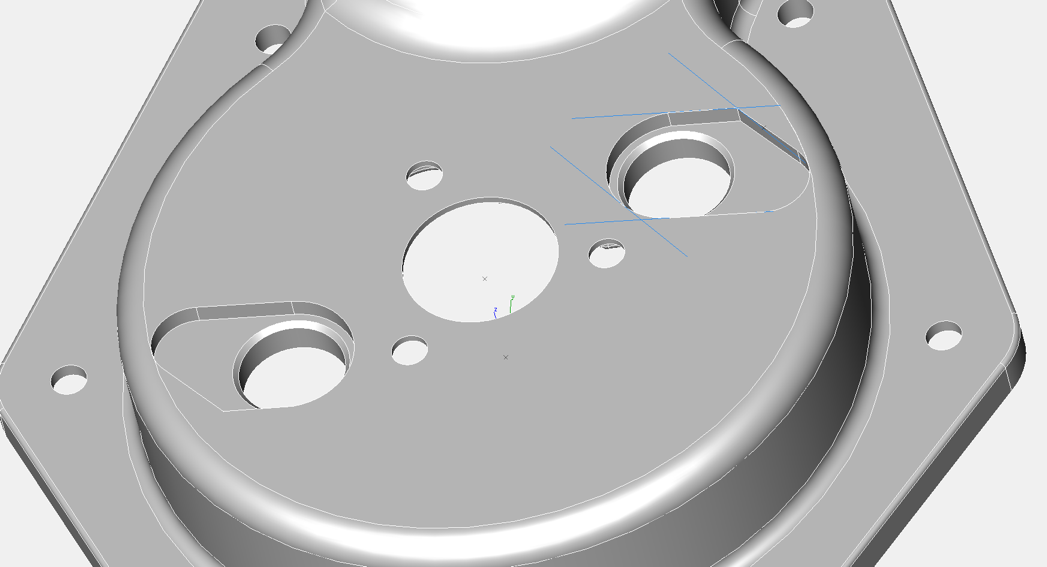

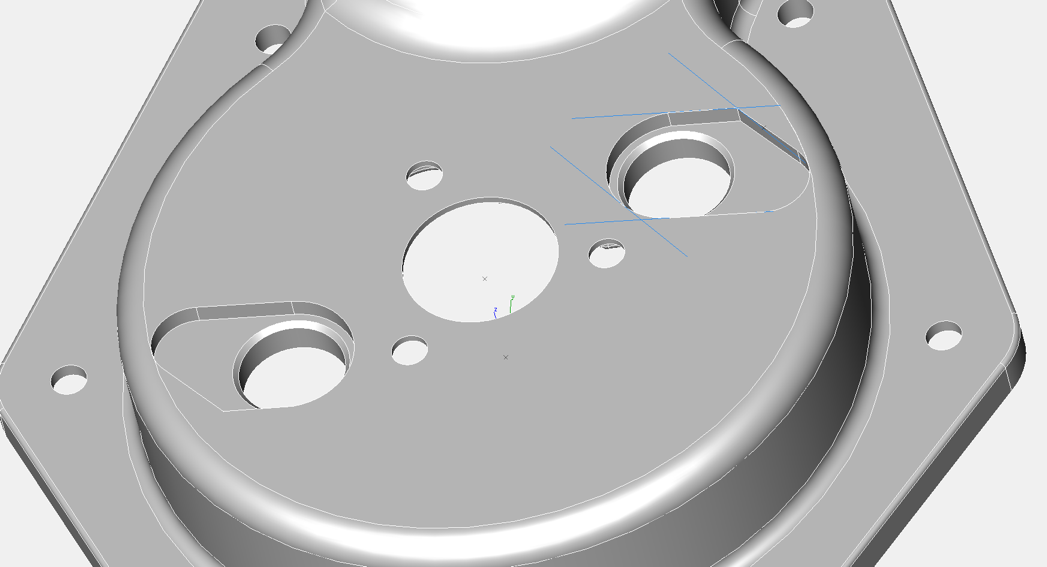

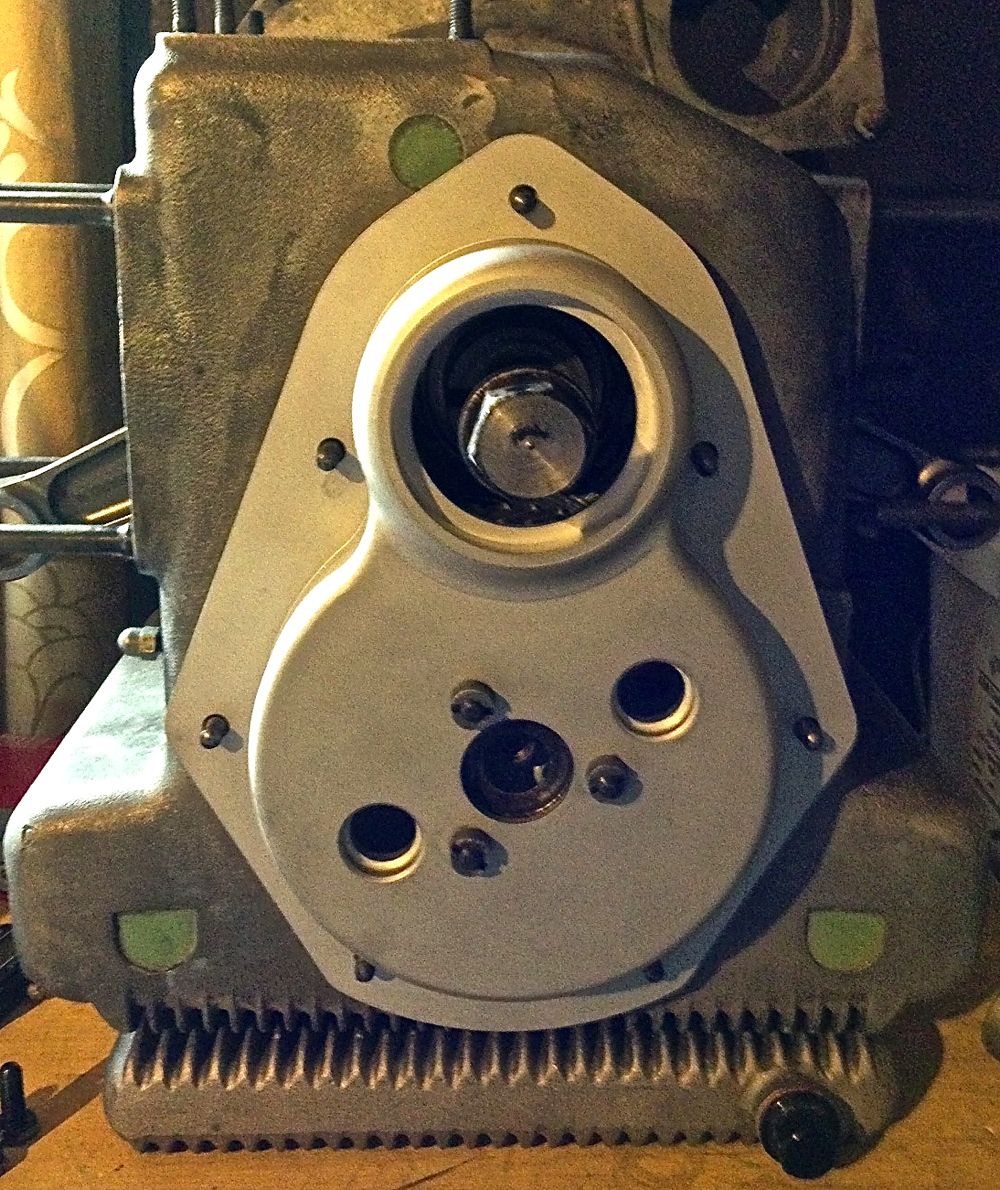

Panhard Front Timing Cover, Revised again & updated

07/05/13 21:45 Filed in: Panhard Engine | Panhard Ignition

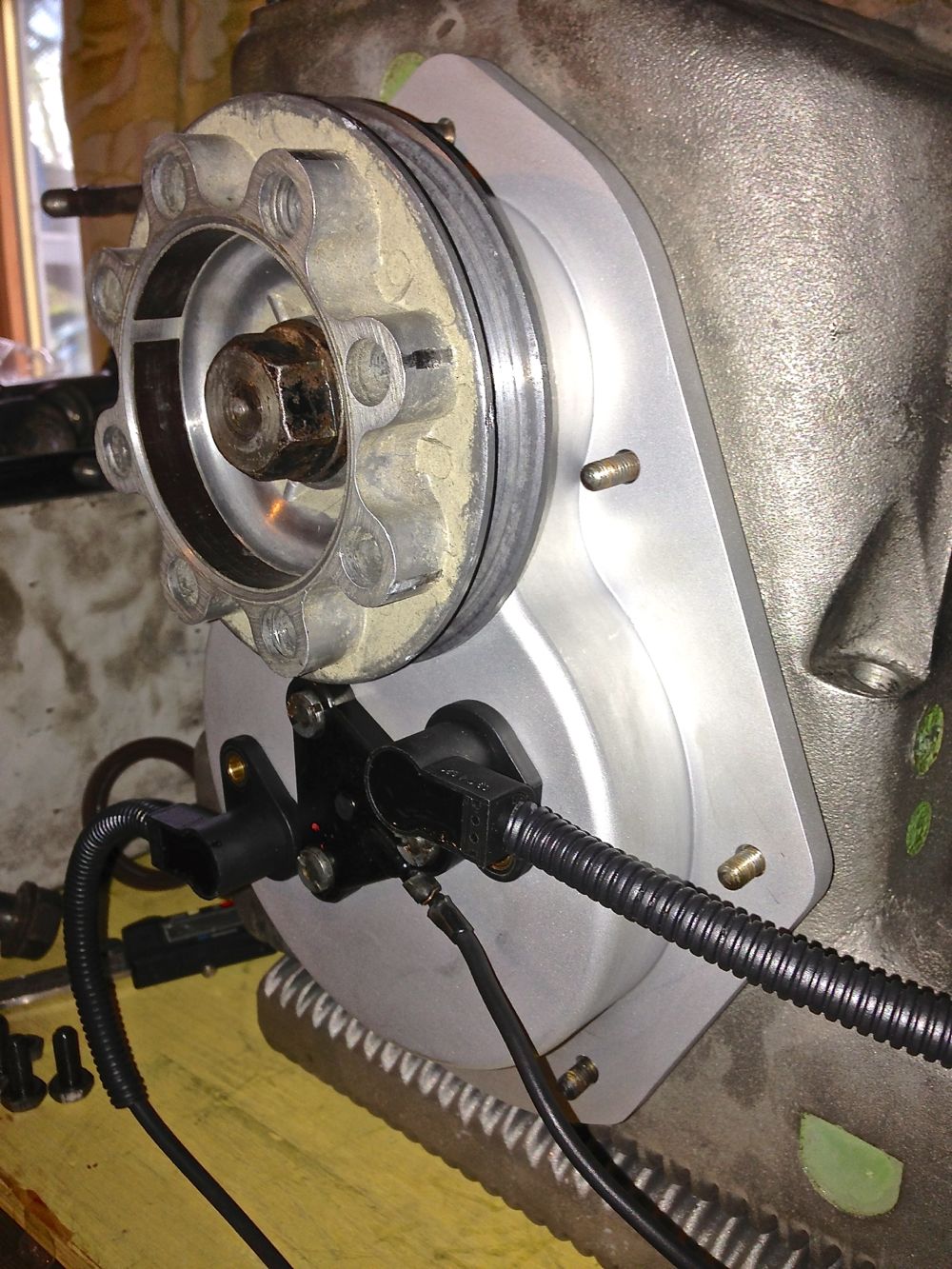

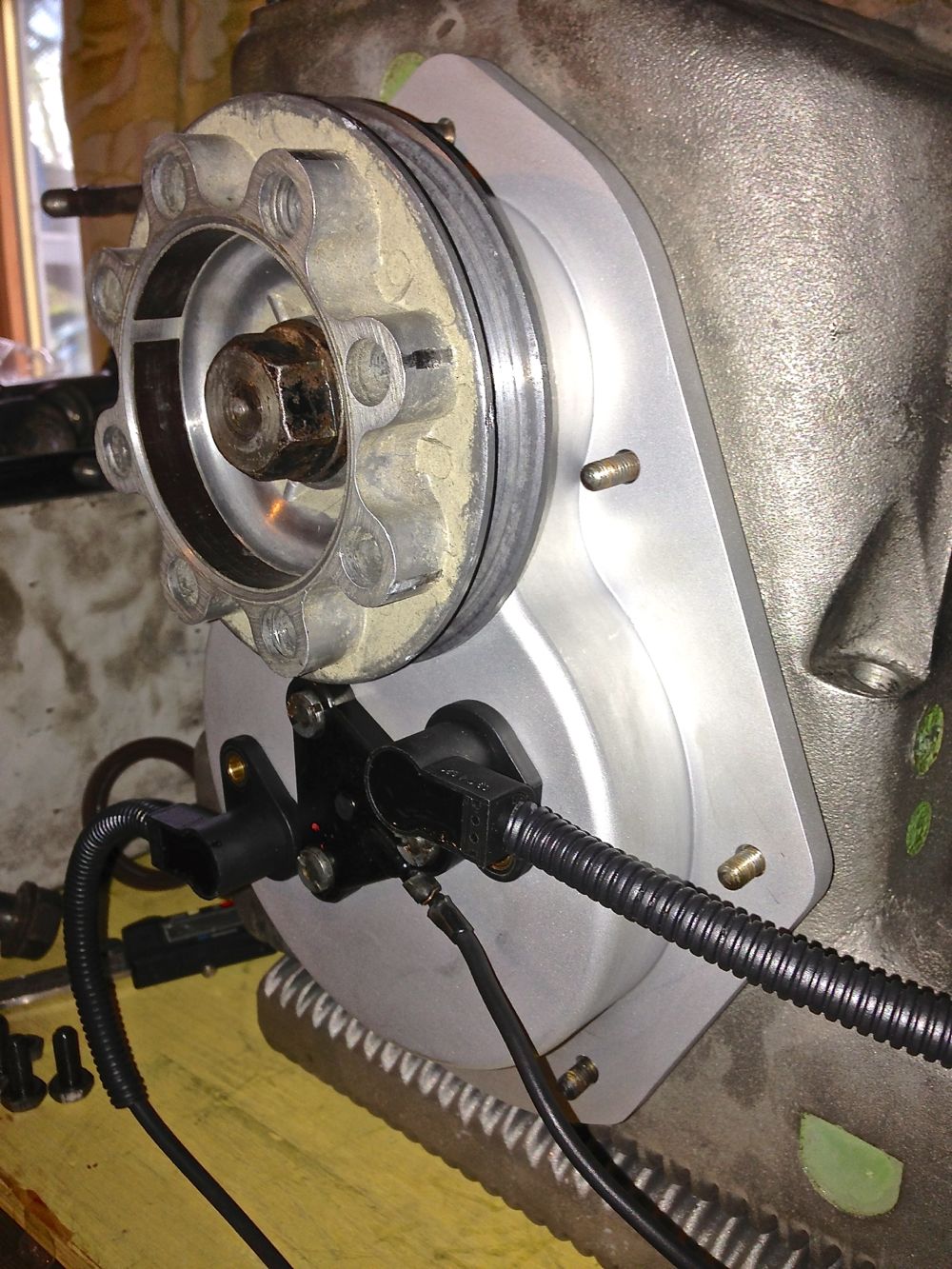

So I got the modded cover back tonight, and after testing the clearances at the oil light switch and the sensor to fan, I realised that the first batch need another tweak, but that’ll have to do for the next batch.

I have simplified the sensor through hole (pictured above), and recessed the sensor by another millimetre for this batch. The oil light internal depth is as far machined as I can go, and ideally needed another millimetre here, so I modded my oil light piston, essentially just making it shorter. Nothing is bolted down in the pictures, as I am just testing the fit, although I did use a multimeter to confirm the action of the oil light switch contacts.

Tomorrow, I’ll do a final test fit for the sensor body into the recessed area, and that’ll be that for this batch.

In the future I will tweak the design slightly, but that’ll be just for the oil light operation.

I have simplified the sensor through hole (pictured above), and recessed the sensor by another millimetre for this batch. The oil light internal depth is as far machined as I can go, and ideally needed another millimetre here, so I modded my oil light piston, essentially just making it shorter. Nothing is bolted down in the pictures, as I am just testing the fit, although I did use a multimeter to confirm the action of the oil light switch contacts.

Tomorrow, I’ll do a final test fit for the sensor body into the recessed area, and that’ll be that for this batch.

In the future I will tweak the design slightly, but that’ll be just for the oil light operation.

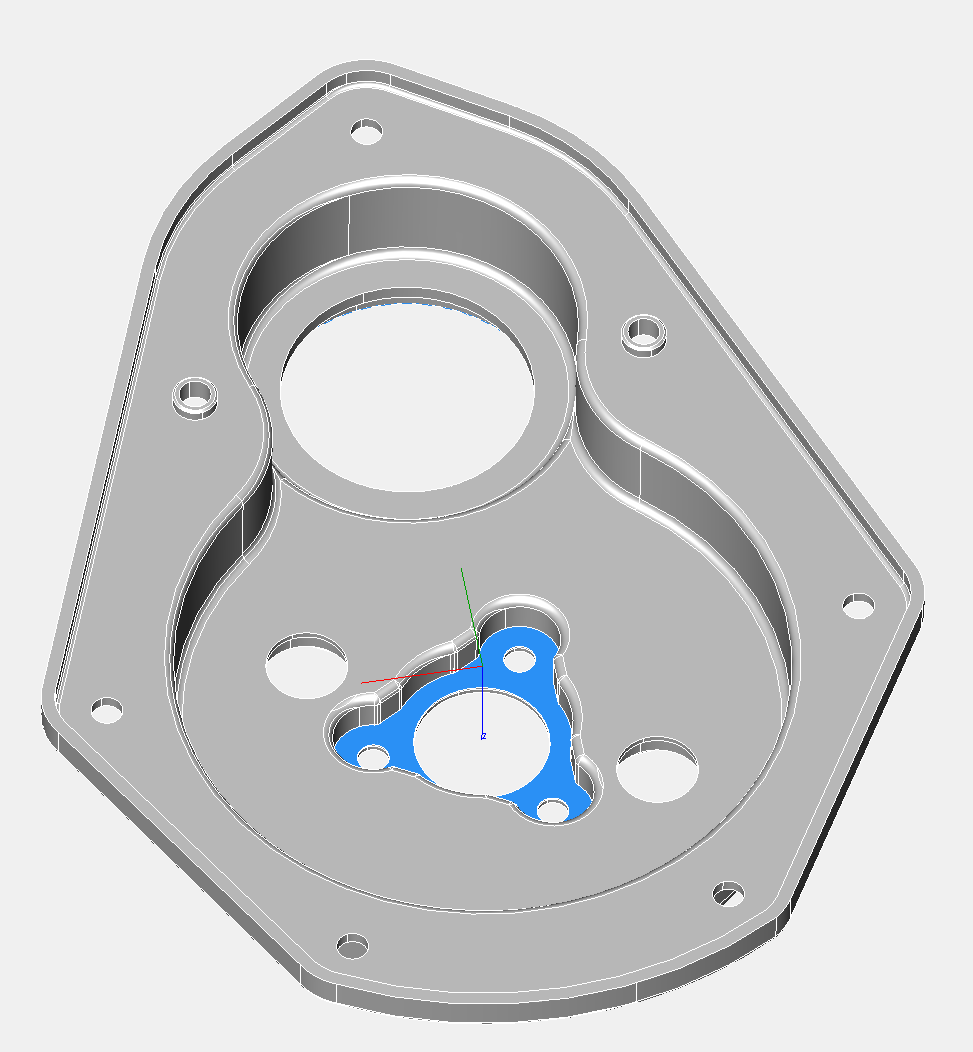

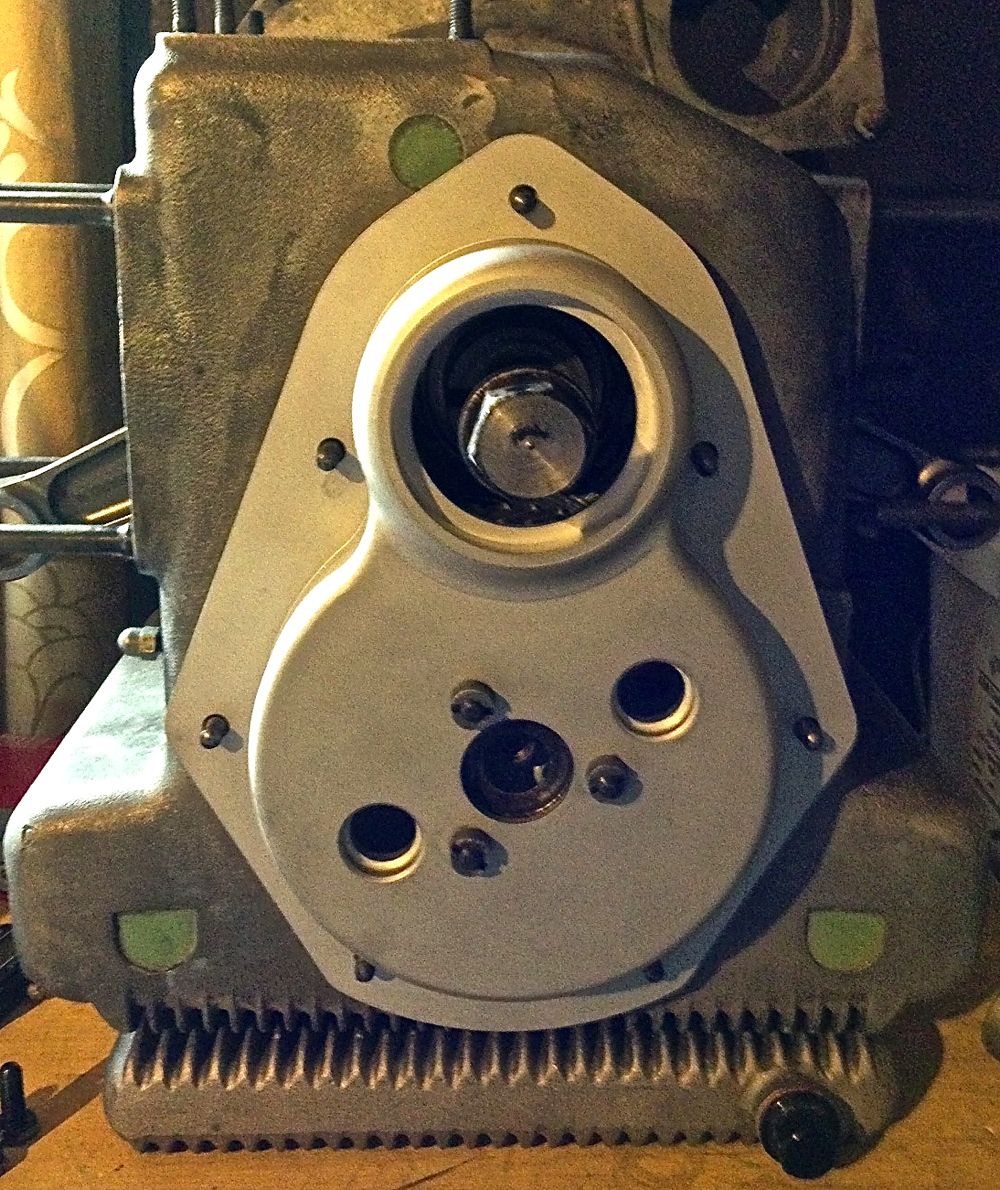

Panhard Front Timing Cover Sensor Fit & Update

05/05/13 18:59 Filed in: Panhard Engine | Panhard Ignition

Last night I was sitting pretty, so to speak, but this morning I decided to fit the wooden blocks and springs to mount the front fan assembly and check the clearance on Brian’s engine. After torquing up the pulley centre bolt, I noticed a few millimetres of clearances, but on rotating the turbine or fan, it scraped the top of the sensor.

I have never seen a misshaped turbine before, so I tried several different ones I had lying around, and surprisingly they were all misshaped, with the resultant wobbling just catching the top of the sensor at some point, so obviously more clearance was needed.

I had two options change the sensor, or recess the sensor some more, and as all my work on the sensor was completed and it is a cost effective (aka cheap) solution with excellent sensitivity, I was reluctant to change the former. This meant recessing the sensor into the timing cover. As I looked at this, I thought I’d check the oil light function, and this too was just too tight a fit, such that the oil light would never illuminate, which isn’t a bad thing, but it isn’t how I intended things to operate.

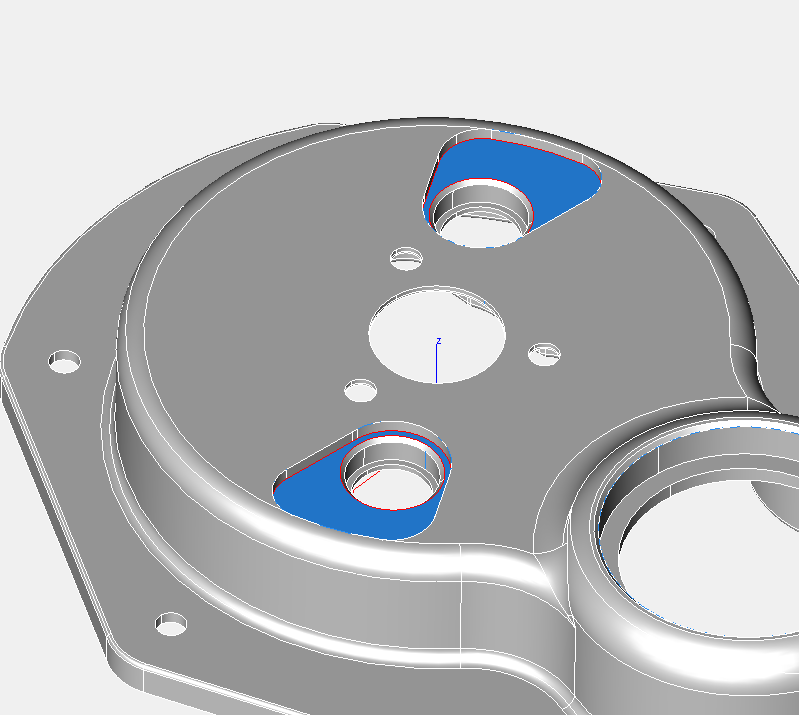

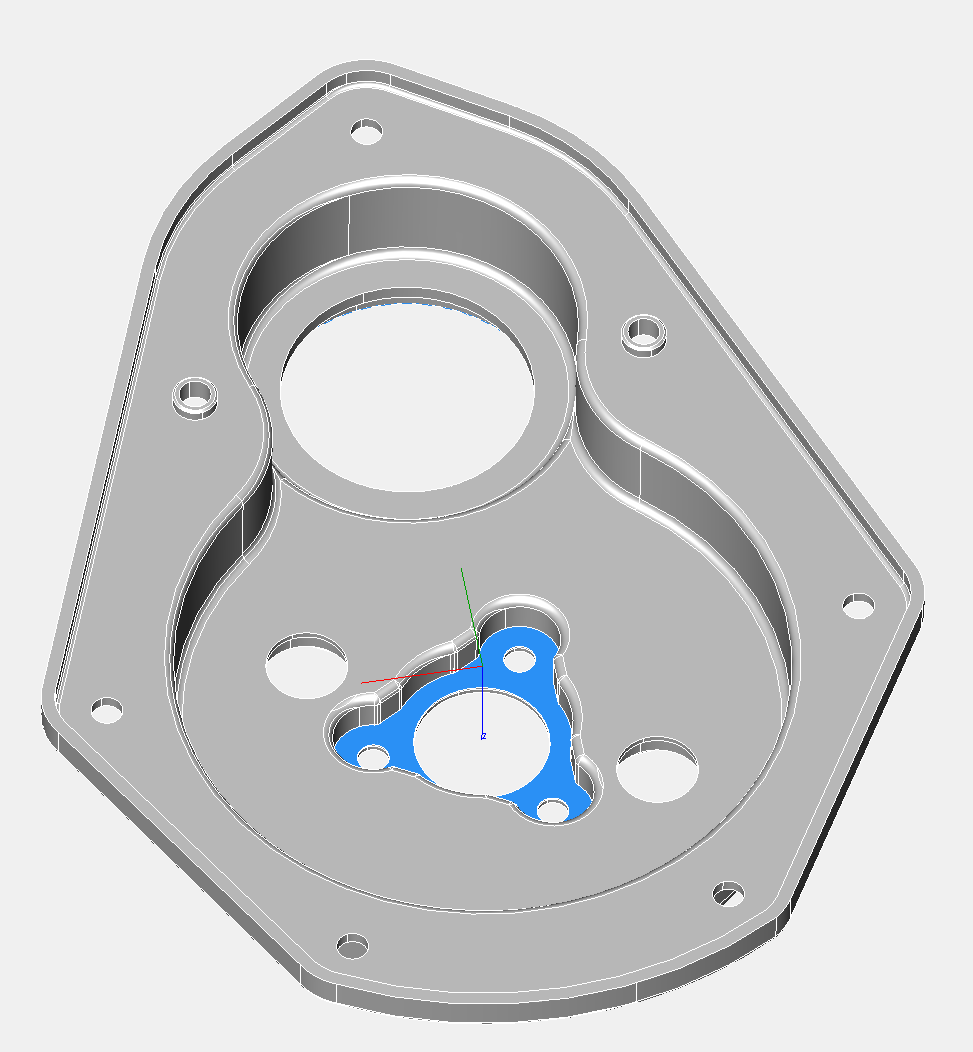

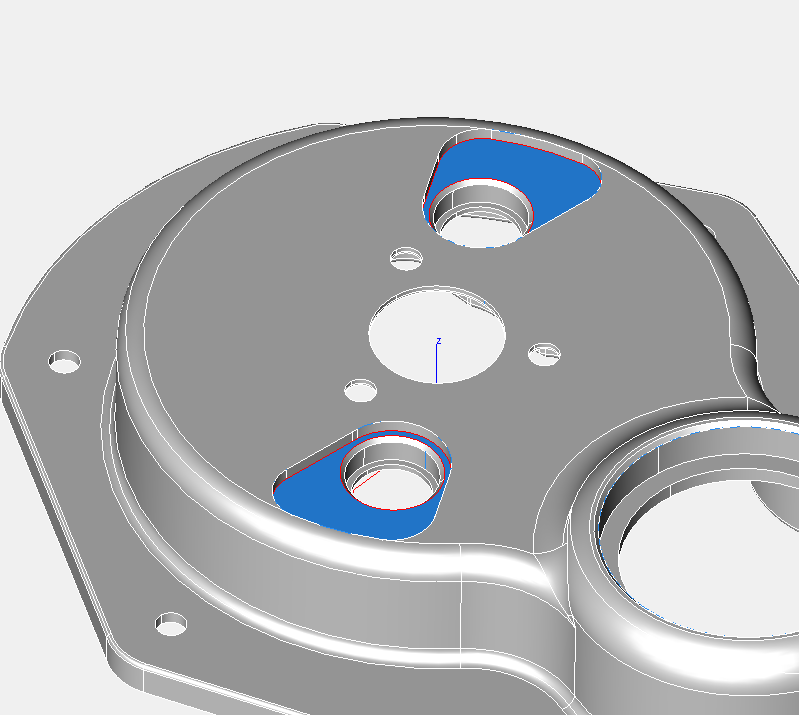

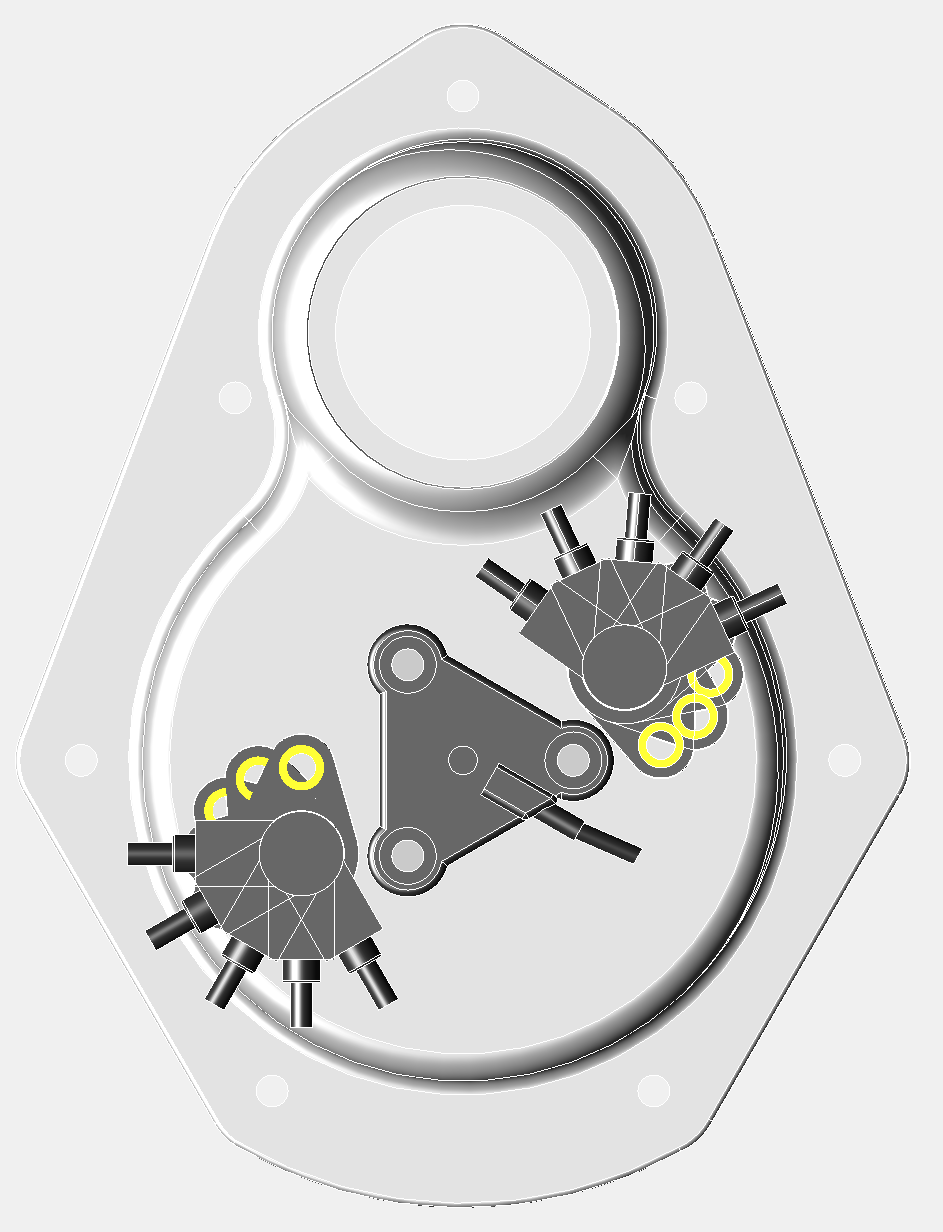

So a quick 3D tweak was in order, and this has been passed onto the 3D CNC fabricator. Slightly annoying for him, but better for us all. Oil light switch surface has been reduced in thickness (blue area) in the picture below, and below this the recessed area to add more sensor to turbine clearance. Not quite as elegant as I’d like, but it’ll do for now, and after testing there might be a slight refinement for the next batch.

PS I thought I would weigh this part, and check the calculated weight in the CAD model versus the actual weight. The CAD model suggested 719 grams, but the actual weight was 723 grams, which is pretty close, and well within 1%. Incidentally, the standard part weighed around 530 grams, but this new timing cover is considerably thicker in places.

I have never seen a misshaped turbine before, so I tried several different ones I had lying around, and surprisingly they were all misshaped, with the resultant wobbling just catching the top of the sensor at some point, so obviously more clearance was needed.

I had two options change the sensor, or recess the sensor some more, and as all my work on the sensor was completed and it is a cost effective (aka cheap) solution with excellent sensitivity, I was reluctant to change the former. This meant recessing the sensor into the timing cover. As I looked at this, I thought I’d check the oil light function, and this too was just too tight a fit, such that the oil light would never illuminate, which isn’t a bad thing, but it isn’t how I intended things to operate.

So a quick 3D tweak was in order, and this has been passed onto the 3D CNC fabricator. Slightly annoying for him, but better for us all. Oil light switch surface has been reduced in thickness (blue area) in the picture below, and below this the recessed area to add more sensor to turbine clearance. Not quite as elegant as I’d like, but it’ll do for now, and after testing there might be a slight refinement for the next batch.

PS I thought I would weigh this part, and check the calculated weight in the CAD model versus the actual weight. The CAD model suggested 719 grams, but the actual weight was 723 grams, which is pretty close, and well within 1%. Incidentally, the standard part weighed around 530 grams, but this new timing cover is considerably thicker in places.

Panhard Front Timing Cover Sensor Fit

04/05/13 18:33 Filed in: Panhard Ignition | Panhard Engine

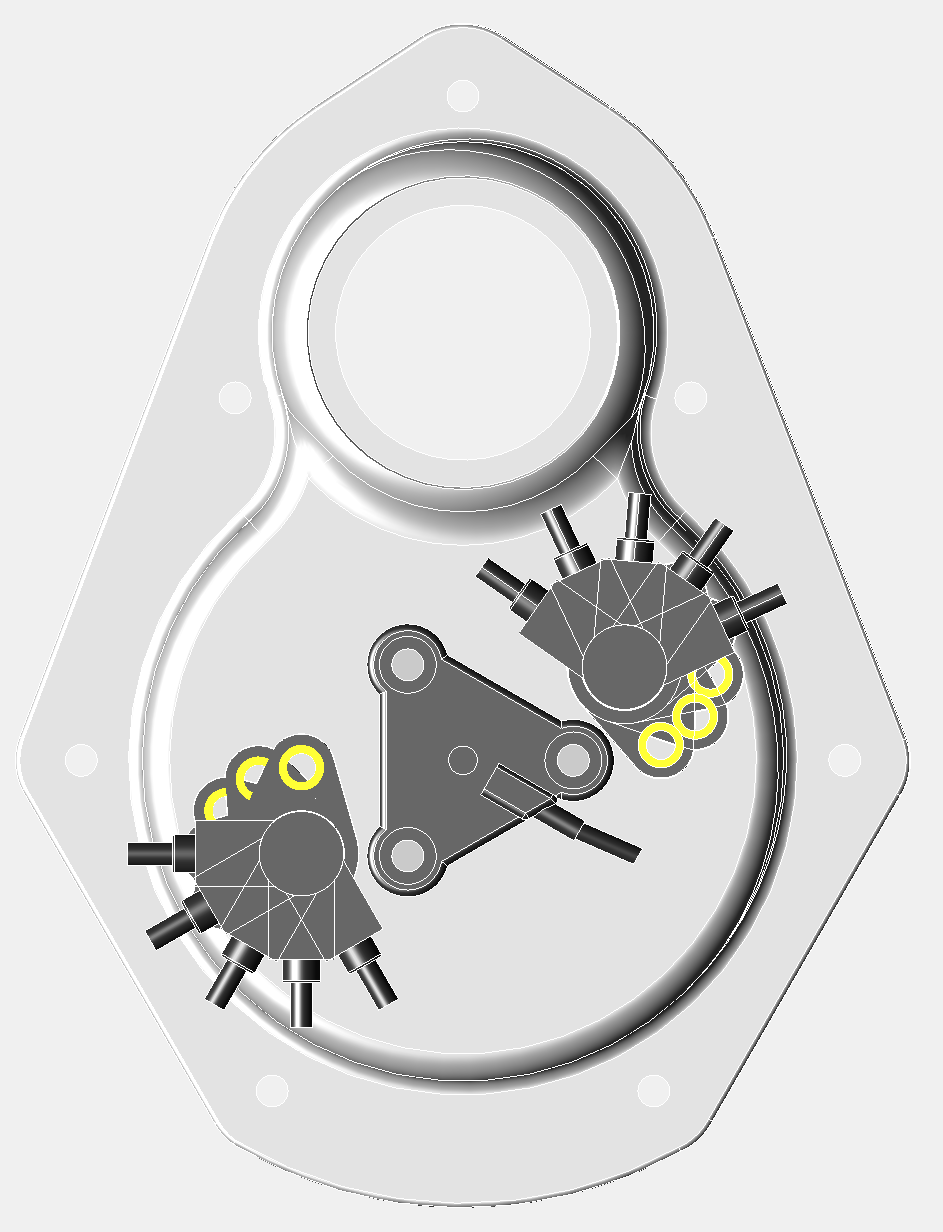

I noticed when I was testing the sensors that these parts are orientation sensitive, so I created an orientation map to help me when it came to fitting the sensors.

It was just a s well, because when I fitted the crankshaft pulley, I noticed the right hand sensor had very few options. The cable will foul the pulley, unless it is in the 1 or 2 o’clock positions, and it is best if it is tangental to the pulley, as this gives more room for dynamo V belt replacement. This is only really a consideration, as I am using sequential twin spark with the Imfsoft Ignition TCI module, and if I used a MicroSquirt, I could just use a single sensor and a toothed wheel. This will also be the case with electronic fuel injection too.

Notice how the Gelbey oil light sensor is rotated, which gives more clearance for sensor rotation.

Tangental orientation below.

Next up was to check the cowling & fan fit

.

After this check the fan clearance, this is the front view, and how discreet is this cover. You wouldn’t realise it was there

More importantly the clearance for the lower left hand sensor! Pretty tight, except the fan is pushed 5mm further forward if my measurements are right (phew)!

All in all, not a bad first stab, even if I do say so myself!

It was just a s well, because when I fitted the crankshaft pulley, I noticed the right hand sensor had very few options. The cable will foul the pulley, unless it is in the 1 or 2 o’clock positions, and it is best if it is tangental to the pulley, as this gives more room for dynamo V belt replacement. This is only really a consideration, as I am using sequential twin spark with the Imfsoft Ignition TCI module, and if I used a MicroSquirt, I could just use a single sensor and a toothed wheel. This will also be the case with electronic fuel injection too.

Notice how the Gelbey oil light sensor is rotated, which gives more clearance for sensor rotation.

Tangental orientation below.

Next up was to check the cowling & fan fit

.

After this check the fan clearance, this is the front view, and how discreet is this cover. You wouldn’t realise it was there

More importantly the clearance for the lower left hand sensor! Pretty tight, except the fan is pushed 5mm further forward if my measurements are right (phew)!

All in all, not a bad first stab, even if I do say so myself!

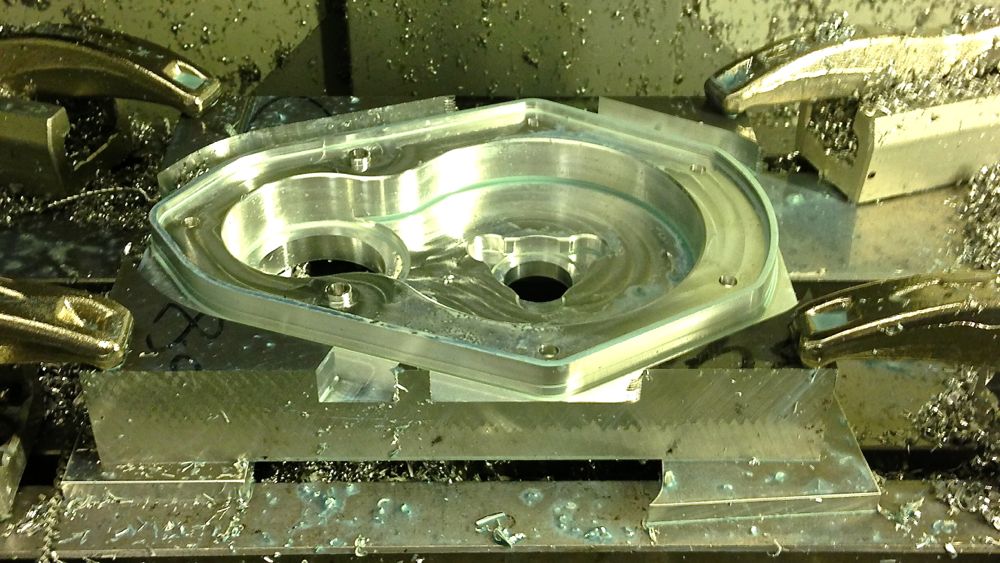

Panhard Front Timing Cover First Fit

04/05/13 12:43 Filed in: Panhard Engine | Panhard Ignition

Just a quick update again, as I have to jump on the lathe in a moment, more of a quick snap for Brian, as he’s got broadband now!

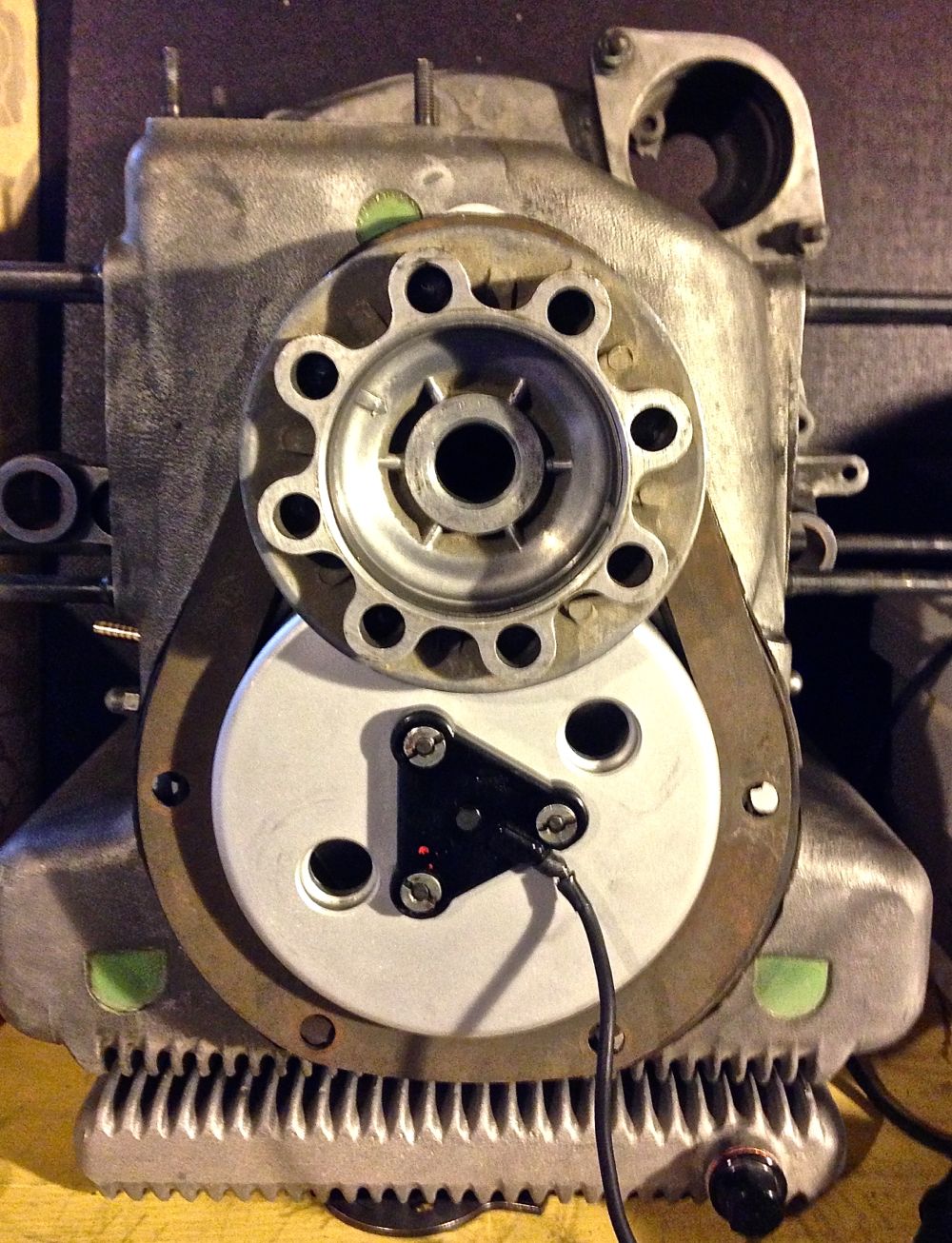

The first trial fit on a crankcase went exceptionally well, as the cover fits snuggly with no discernible play on the locating dowels.

There were two minor issues, one the oil light piston tab washer detail was slightly too small, and two, the O ring seal could be marginally tighter on the sensor holes, but all these have details have been corrected in the 3D model now, so the rest of this batch will be spot on.

I am extremely pleased with the results so far, and even better, there is sufficient room for the various trigger wheel configurations I have planned.

I will update the pictures again later.

The first trial fit on a crankcase went exceptionally well, as the cover fits snuggly with no discernible play on the locating dowels.

There were two minor issues, one the oil light piston tab washer detail was slightly too small, and two, the O ring seal could be marginally tighter on the sensor holes, but all these have details have been corrected in the 3D model now, so the rest of this batch will be spot on.

I am extremely pleased with the results so far, and even better, there is sufficient room for the various trigger wheel configurations I have planned.

I will update the pictures again later.

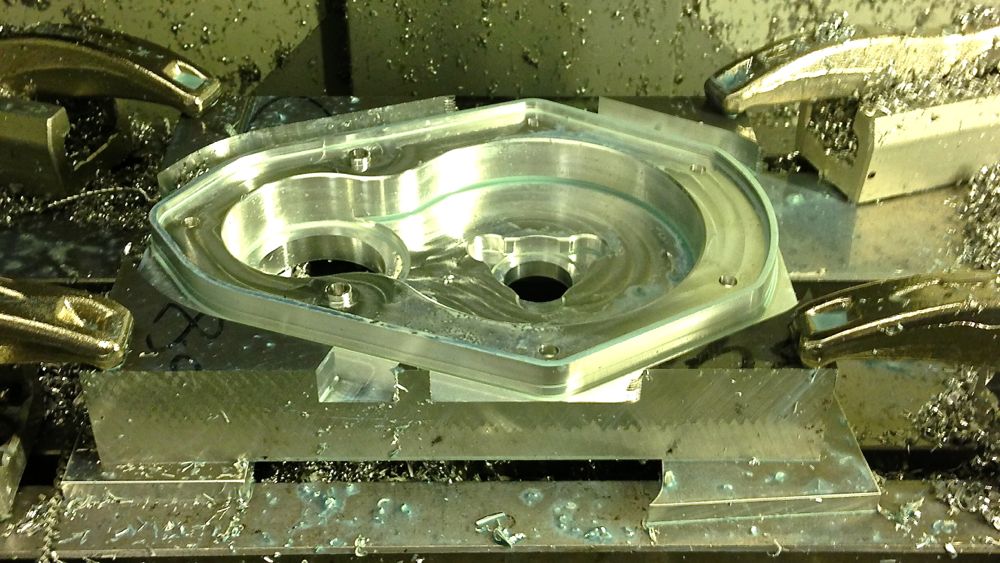

Panhard Front Timing Cover CNC Started

03/05/13 17:40 Filed in: Panhard Engine | Panhard Ignition