Panhard Cylinder Liner Rebore Update 1

23/09/12 14:18 Filed in: Panhard Piston | Whatton

I recently bought an upgraded version of the original motor off eBay, a 370W or 1/2 horsepower with the correct baseplate. However when I tried to swap the motor over today, I discovered the increased height or length didn’t allow it to clear the main casting. I had to revert back to the old motor, but I did use the cush drive off the vacuum pump, which was more concentric than the old part, and the boring machine is much quieter, with less vibration.

I have been doing all the attempted cuts so far with a single belt, and really struggled to fit one belt let alone the two that are required. Today I managed to fit the sister belt, a Z16 428 Ld, 410 Li onto the double fee pulley. It was at this point I notice the other belt was slightly stretched and greasy. The frayed edges are a result of a woodruff key being fitted incorrectly by the previous owner, it should never had one, as it had a hardened circular pin, that located in a vertical keyway. The woodruff key grabbed and wore itself out, and caused the belt to run at an angle, so cutting the edges.

I cannot guarantee I will get the same, so I have ordered two new belts to replace the stretched one. I also have a novel way (new to me) of getting the vee belt onto the pulleys, which doesn’t involve taking the pulleys off and sliding them down the shafts, however I cannot tell you how, as it might mean a silly person could lose a finger. Suffice to say, I cannot turn the pulleys by hand to get the belt to fall into its respective groove without it needing some electrical assistance.

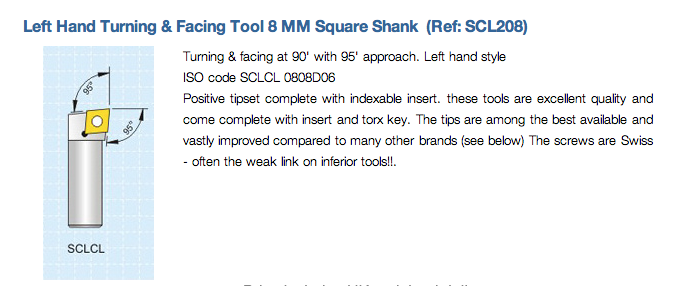

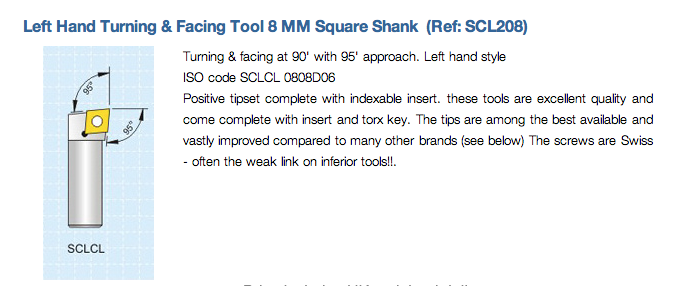

The tooltips were scheduled to be done today, but I am pleased they haven’t been done yet as I have bought another LH boring tool to convert, and so I don’t have to pay for another set up charge.

It’s 8mm square shanked, indexable and takes CCMT inserts, but I am having it shortened and made 5/16” round with a flat put on it to lock it off square in the boring head tooltip carrier.

Hopefully, I will be able to use them soon, within the first week of October, in the boring machine, and then get the test liner analysed for surface finish, squareness etc at the local engineering works. If all works out, I will be able to rebore Panhard liners in the future to very precise standards.

I have been doing all the attempted cuts so far with a single belt, and really struggled to fit one belt let alone the two that are required. Today I managed to fit the sister belt, a Z16 428 Ld, 410 Li onto the double fee pulley. It was at this point I notice the other belt was slightly stretched and greasy. The frayed edges are a result of a woodruff key being fitted incorrectly by the previous owner, it should never had one, as it had a hardened circular pin, that located in a vertical keyway. The woodruff key grabbed and wore itself out, and caused the belt to run at an angle, so cutting the edges.

I cannot guarantee I will get the same, so I have ordered two new belts to replace the stretched one. I also have a novel way (new to me) of getting the vee belt onto the pulleys, which doesn’t involve taking the pulleys off and sliding them down the shafts, however I cannot tell you how, as it might mean a silly person could lose a finger. Suffice to say, I cannot turn the pulleys by hand to get the belt to fall into its respective groove without it needing some electrical assistance.

The tooltips were scheduled to be done today, but I am pleased they haven’t been done yet as I have bought another LH boring tool to convert, and so I don’t have to pay for another set up charge.

It’s 8mm square shanked, indexable and takes CCMT inserts, but I am having it shortened and made 5/16” round with a flat put on it to lock it off square in the boring head tooltip carrier.

Hopefully, I will be able to use them soon, within the first week of October, in the boring machine, and then get the test liner analysed for surface finish, squareness etc at the local engineering works. If all works out, I will be able to rebore Panhard liners in the future to very precise standards.

blog comments powered by Disqus